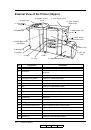

Printer Overview

1-3

OG

L

0 1

Component-based consumables.

User replaceable toner and staples.

High-volume printing.

Three standard paper cassettes with approximately 3000-sheet capacity total

and the Multi-bypass Tray (MBT) with a 150-sheet capacity.

Optional High Capacity Feeder (HCF) adds up to 3000 additional sheets.

Together they allow continuous printing of up to 6150 sheets.

Supports a wide-range of media types ( bond, letterhead, special ,recycled,

transparencies, labels) and sizes.

See “Paper” on page 3-2

for more information.

Printer Language Support.

Optional PostScript 3 (Adobe) printer language.

PCL5e and PCL XL printer language.

TIFF and PDF data format

Network.

Ethernet 10/100 Base-T.

Network Protocol.

TCP/IP and LPR/LPD with onboard network.

TCP/IP, LPR/LPD, NetWare IPX, SPX, Ethertalk, with optional PSM card.

IPP

Easy installation of additional fonts and macros using the PCL Startup File.

I/O Configurations

Bi-directional 1284C Parallel interface with Compatibility, Nibble, Byte, and

ECP Mode support.

Ethernet 10/100 Base-T.