14

English

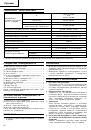

OPTIONAL ACCESSORIES (SOLD SEPARATELY)

(1) Extension Holder and Stopper

(2) Crown molding Vise Ass'y (Include Crown molding

Stopper (L))

(3) Crown molding Stopper (L)

(4) Crown molding Stopper (R)

Optional accessories are subject to change without notice.

APPLICATION

䡬

Cutting various types of aluminium sash and wood.

UNPACKING

䡬

Carefully unpack the power tool and all related items

(standard accessories).

䡬

Check carefully to make certain all related items

(standard accessories) are present.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position. If

the plug is connected to a receptacle while the trigger

switch is in the ON position, the power tool will start

operating immediately, inviting serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be kept

as short as practicable.

4. When the power tool is prepared for shipping, its

main parts are secured by a locking pin

Move the handle slightly so that the locking pin can

be disengaged.

CAUTION

䡬

Set for transport

Lock the locking pin into the gear case (Fig. 3).

Remove a 6 mm wing bolt.Turn the turn plate as the

Fig. 5, and fix it again with the 6 mm wing bolt.

Lower guard cover the teeth of the blade to the front

of the machine.

䡬

Cutting work

Move the handle slightly so that the locking pin can

be disengaged.

Remove a 6 mm wing bolt.Turn the turn plate as Fig.

6, and fix it again with the 6 mm wing bolt.

5. Attach the dust bag to the main unit (Fig. 1)

(1) When the dust bag has become full of sawdust, dust

will be blown out of the dust bag when the saw blade

rotates.

Check the dust bag periodically and empty it before it

becomes full.

(2) During bevel and compound cutting, attach the dust

bag at a right angle to the base surface as shown in

Fig. 4.

CAUTION

䡬

Empty the dust bag frequently to prevent the duct and

the safety cover from becoming clogged.

Sawdust will accumulate more quickly than normal

during bevel cutting.

6. Installation

Ensure that the machine is always fixed to bench.

Attach the power tool to a level, horizontal work bench.

Select 8 mm diameter bolts suitable in length for the

thickness of the work bench.

Bolt length should be at least 35 mm plus the thickness

of the work bench.

For example, use 8 mm

×

60 mm bolts for a 25 mm

thick work bench.

ADJUSTING THE POWER TOOL PRIOR TO USE

CAUTION

Make all necessary adjustments before inserting the

plug in the power source.

1. Check to see that the lower guard operates smoothly

CAUTION

䡬

This compound miter saw is equipped with a saw

head lock as safety device.

䡬

To lower the saw head to cut, the lock must be released

by pressing the lock lever (C) with your thumb.

(1) When you push down the handle while pushing the

lock lever (C), check that the lower guard revolves

smoothly (Fig. 7).

(2) Next, check that the lower guard returns to the original

position when the handle is raised.

PRACTICAL APPLICATIONS

WARNING

䡬

To avoid personal injury, never remove or place a

workpiece on the table while the tool is being

operated.

䡬

Never place your limbs inside of the line next to

warning sign while the tool is being operated. This

may cause hazardous conditions (see Fig. 8).

CAUTION

䡬

It is dangerous to remove or install the workpiece

while the saw blade is turning.

䡬

When sawing, clean off the shavings from the

turntable.

䡬

If the shavings accumulate too much, the saw blade

from the cutting material will be exposed. Never

subject your hand or anything else to go near the

exposed blade.

1. Tightly secure the material by vise assembly to be

cut so that it does not move during cutting

2. Switch operation

Pulling the trigger turns the switch on. Releasing the

trigger turns the switch off.

3. Holder (B), clamp lever adjustment (Fig. 9)

Attach the included holder (B) in the position as shown

in Fig. 9 and adjust the holder (B) until its bottom

surface contacts the work bench surface. After

adjustments, securely tighten the 6mm bolt with the

included 10mm box wrench. Loosen the M6

×

20 screw

on the clamp lever and attach to a position where the

clamp lever can be easily operated.

4. Using the Vise Assembly (Standard accessory) (Fig. 10)

(1) The vise assembly can be mounted on either the left

fence {Fence (B)} or the right fence {Fence (A)} by

loosening the 6 mm wing bolt (A).

(2) The screw holder can be raised or lowered according

to the height of the workpiece by loosening the 6 mm

wing bolt (B). After the adjustment, firmly tighten the

6 mm wing bolt (B) and fix the screw holder.