87

71.03982.03 - EN

INSTALLATION INSTRUCTIONS

To measure combustion eficiency and the toxicity of the products of combustion, the boiler is itted with two dedicated

test points.

One connection point is connected to the exhaust duct and is used to measure combustion eficiency and the toxicity of

the products of combustion.

The other is connected to the air intake circuit and is used to check for the presence of any products of combustion

circu¬lating in installations with co-axial lues.

The following parameters can be measured using the test point connected to the exhaust duct:

• temperature of the products of combustion;

• concentration of oxygen (O

2

) or, alternatively, carbon dioxide (CO

2

);

• concentration of carbon monoxide (CO).

The temperature of the comburent air must be measured on the test point located on the air intake lue by inserting the

measurement sensor by about 3 cm.

N.B.:

to regulate the rated power, see chapter 19 (B1)

For natural draught boiler models, a hole must be made in the exhaust lue at a distance from the boiler equal to twice

the internal diameter of the lue.

The following parameters can be measured through this hole:

• temperature of the products of combustion;

• concentration of oxygen (O

2

) or, alternatively, carbon dioxide (CO

2

);

• concentration of carbon monoxide (CO).

The temperature of the combustion air must be measured close to the point where the air enters the boiler. The hole,

which must be made by the person in charge of the system during commissioning, must be sealed so as to ensure that

the exhaust duct is airtight during normal operation.

24. CHECKING COMBUSTION PARAMETERS

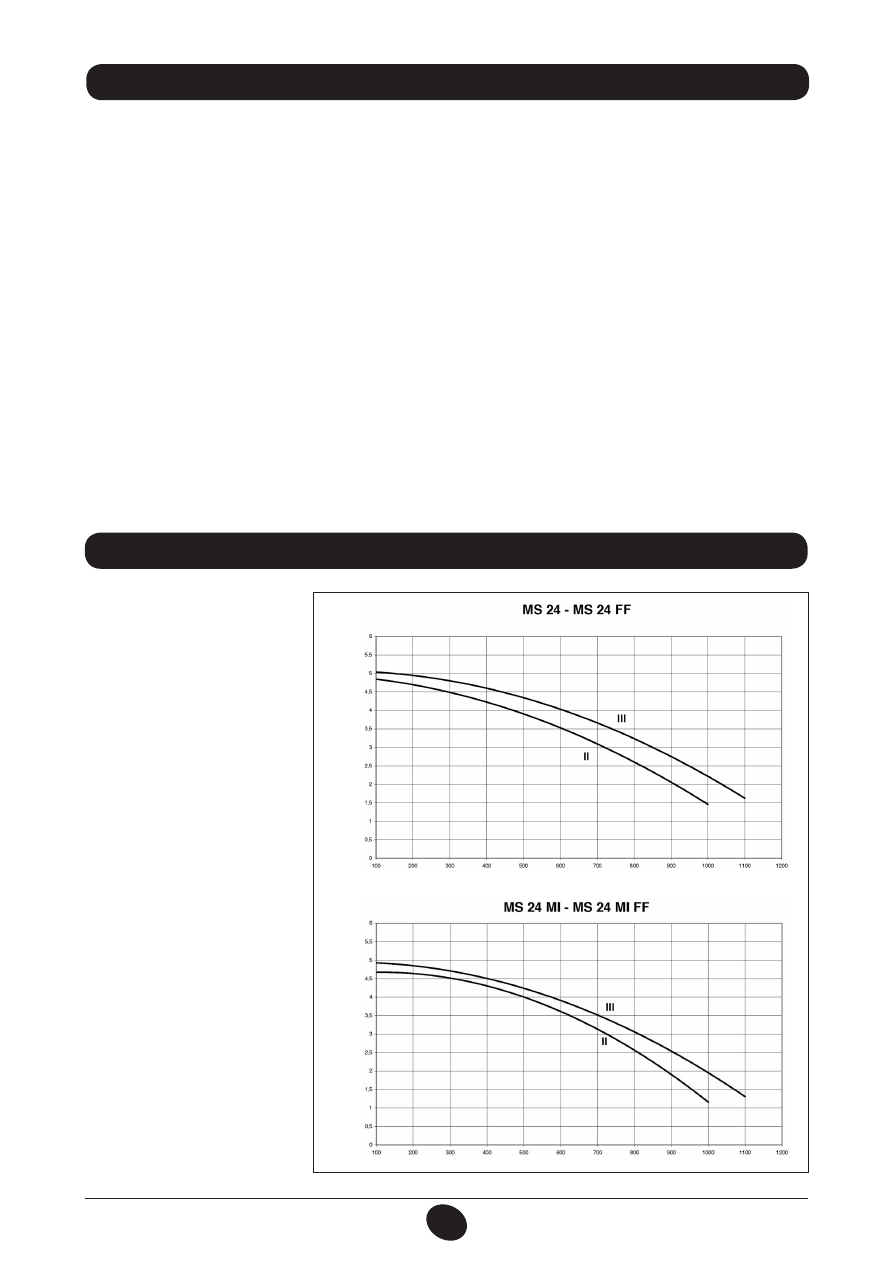

25. PUMP CAPACITY/ HEAD

A high static head pump (GRUN-

DFOS UPSO 15-50), suitable for

installation on any type of single- or

double-pipe heating system, is used.

The automatic air valve incorporated

in the pump allows quick venting of

the heating system.

Graph 1

FLOW l/h

HEAD mH

2

O

1009_2401

1009_2402

FLOW l/h

HEAD mH

2

O