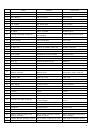

21

English

NOTE

䡬

Before starting to cut, align the main unit to the miter angle 0° and the bevel

angle 0° and hold down the reset buttons for at least 0.2 second. If you press

the digital display switch to ON without aligning the main unit to 0°, then the

figures appearing on the digital display and the main unit angle will not

match.

䡬

The laser marker will not light up if the digital display switch is turned off.

(only on C12LSH)

䡬

Do not use the main unit near equipment that generates electrical noise

such as generators. Electrical noise might cause faulty readings or operation

on the digital display.

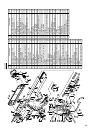

13. Cutting operation

(1) As shown in Fig. 21 the width of the saw blade is the width of the cut.

Therefore, slide the workpiece to the right (viewed from the operator’s

position) when length

is desired, or to the left when length

is desired.

If a laser marker is used, align the laser line with the left side of the saw

blade, and then align the ink line with the laser line.

(2) After turning on the switch and checking that the saw blade is rotating at

maximum speed, slowly push down the handle while holding down the lever

(A) and bring the saw blade in the vicinity of the material to be cut.

(3) Once the saw blade contacts the workpiece, push the handle down gradually

to cut into the workpiece.

(4) After cutting the workpiece to the desired depth, turn the power tool OFF

and let the saw blade stop completely before raising the handle from the

workpiece to return it to the full retract position.

CAUTION

䡬

For maximum dimensions for cutting, refer to “SPECIFICATIONS” table.

䡬

Increased pressure on the handle will not increase the cutting speed. On the

contrary, too much pressure may result in overload of the motor and/or

decreased cutting efficiency.

䡬

Confirm that the trigger switch is turned OFF and the power plug has been

removed from the receptacle whenever the tool is not in use.

䡬

Always turn the power off and let the saw blade stop completely before

raising the handle from the workpiece. If the handle is raised while the saw

blade is still rotating, the cut-off piece may become jammed against the saw

blade causing fragments to scatter about dangerously.

䡬

Every time one cutting of deep-cutting operation is finished, turn the switch

off, and check that the saw blade has stopped. Then raise the handle, and

return it to the full retract position.

䡬

Be absolutely sure to remove the cut material from the top of the turntable,

and then proceed to the next step.

䡬

Continued cutting operation can result in overload of the motor. Touch the

motor and if it's hot, stop your cutting operation once and rest for 10 minutes

or so, and then restart your cutting operation.

䡬

Do not operate the head section or lift up the main unit while grasping the

digital display (Fig. 1) as this could cause damage to the digital display.

14. Cutting narrow workpieces (Press cutting)

Slide the hinge down to holder (A), then tighten the slide securing knob (A)/(B)

(Fig. 2). Lower the handle to cut the workpiece. Using the power tool this way

will permit cutting of workpieces of up to 107 mm square.

15. Cutting wide workpieces (Slide cutting)

(1) Workpieces up to 107 mm high and 312 mm wide:

Loosen the slide securing knob (A) (Fig. 2), grip the handle and slide the saw

blade forward.

Then press down on the handle and slide the saw blade back to cut the

workpiece. This facilitates cutting of workpieces of up to 107 mm in height

and 312 mm in width.

(2) Workpieces up to 120 mm high and 260 mm wide:

Workpieces of up to 120 mm in height and up to 260 mm in width can be cut

in the same manner as described in paragraph 15-(1) above.

CAUTION

䡬

When cutting a workpiece of 120 mm height, adjust the lower limit position

of the motor head so that the gap between the lower edge of the motor head

and the workpiece will be 2 to 3 mm at the lower limit position.

䡬

If the handle is pressed down with excessive or lateral force, the saw blade

may vibrate during the cutting operation and cause unwanted cutting marks

on the workpiece, thus reducing the quality of the cut.

Accordingly, press the handle down gently and carefully.

䡬

In slide cutting, gently push the handle back (rearwards) in a single, smooth

operation.

Stopping the handle movement during the cut will cause unwanted cutting

marks on the workpiece.

WARNING

䡬

For slide cutting, follow the procedures.

Forward slide cutting (toward the operator) is very dangerous because the

saw blade could kick upward from the workpiece. Therefore, always slide

the handle away from the operator.

䡬

Always return the carriage to the full rear position after each crosscut

operation in order to reduce the risk of injury.

䡬

Never put your hand on the side handle during the cutting operation because

the saw blade comes close to the side handle when the motor head is lowered.

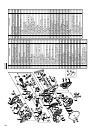

16. Miter cutting procedures

(1) Loosen the side handle and pull up the lever for angle stoppers. Then, adjust

the turntable until the indicator aligns with desired setting on the miter scale

(Fig. 22).

(2) Re-tighten the side handle to secure the turntable in the desired position.

(3) The miter scale indicates both the cutting angle on the angle scale and the

gradient on the grade scale.

(4) The gradient, which is the ratio of the height to the base of the triangular

section to be removed, may be used for setting the miter scale instead of

the cutting angle, if desired.

(5) Therefore, to cut a workpiece at a grade of 2/10, set the indicator to position.

NOTE

䡬

Positive stops are provided at the right and left of the 0° center setting, at

15°, 22.5°, 30° and 45° settings.

Check that the miter scale and the tip of the indicator are properly aligned.

䡬

Operation of the saw with the miter scale and indicator out of alignment, or

with the side handle not properly tightened, will result in poor cutting

precision.

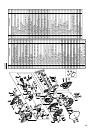

17. Miter angle fine adjustment

(1) Rotate the turntable to the miter angle you need.

(2) When making fine adjustments of the miter angle, turn the knob (A) while

pulling up the lever (Fig. 23).

NOTE

Turning knob (A) clockwise, allows fine adjustment of the turntable to the

right. Turning knob (A)

counterclockwise, allows fine adjustment of the turntable to the left.

(3) After adjusting to the desired angle, tighten the side handle.

CAUTION

Always check that the side handle is secured and the turntable is clamped.

If you attempt angle cutting without clamping the turntable, then the turntable

might shift unexpectedly causing injuries.

18. Bevel cutting procedures

CAUTION

䡬

Ensure that the clamp lever is securely fixed when beveling.

䡬

Please do this if the length of the material being cut off is more than 25 mm

long. Sometimes cutting cannot be accomplished because the saw blade

will catch on the inside of the lower guard.

(1) Loosen the clamp lever and bevel the saw blade to the left or to the right.

When tilting the motor head to the right pull the set pin (A) towards the rear.

The clamp lever adopts a latchet system. When contacting the work bench

and the main body, pull the clamp lever in the direction of the arrow mark as

illustrated in Fig. 24, and change the direction of the clamp lever.

(2) Adjust the bevel angle to the desired setting while watching the bevel angle

scale and indicator, then secure the clamp lever.

WARNING

When the workpiece is secured on the left or right side of the blade, the

short cut-off portion will come to rest on the right or left side of the saw

blade. Always turn the power off and let the saw blade stop completely before

raising the handle from the workpiece.