-

5

Turn bleeder screw (c) ca. 2 rotations

anti-clockwise.

Press button (b) so often until there are

no more air bubbles in the suction hose

and the detergents and drying aid flows

back via run-off hose into the container.

Screw close the bleeder screw (c)

again.

In the event of danger for persons, property

and animals, the plant must be switched off

immediately by pressing the emergency-

stop button. It is found

–

at the wash card/code reader

–

at the operating place for manual oper-

ator station

–

at the entrance to the wash hall, íf an

operating point or wash card/code

reader is located there.

몇

Warning!

Risk of damage to vehicle which is to be

cleaned. If the wash plant develops a fault

once the detergent has been applied, it

must be switched off and the detergent re-

moved by spraying the vehicle thoroughly

with water to prevent the paintwork being

damaged through an extended period of

exposure to the detergent.

몇

Warning

When using Carlite brushes, the vehicle

must be manually cleaned beforehand, if

the appliance is not equipped with an up-

grade kit high pressure!

Note

In the case of self-operating plants, a spe-

cialist familiar with the plant must be con-

tactable who can carry out measures, or

have them done, in order to avoid possible

dangers.

Note

Before switching on again, the cause for

activating the emergency switch button has

to be remedied. Persons or animals may

not remain in the working area. Vehicles

must be driven out of the plant.

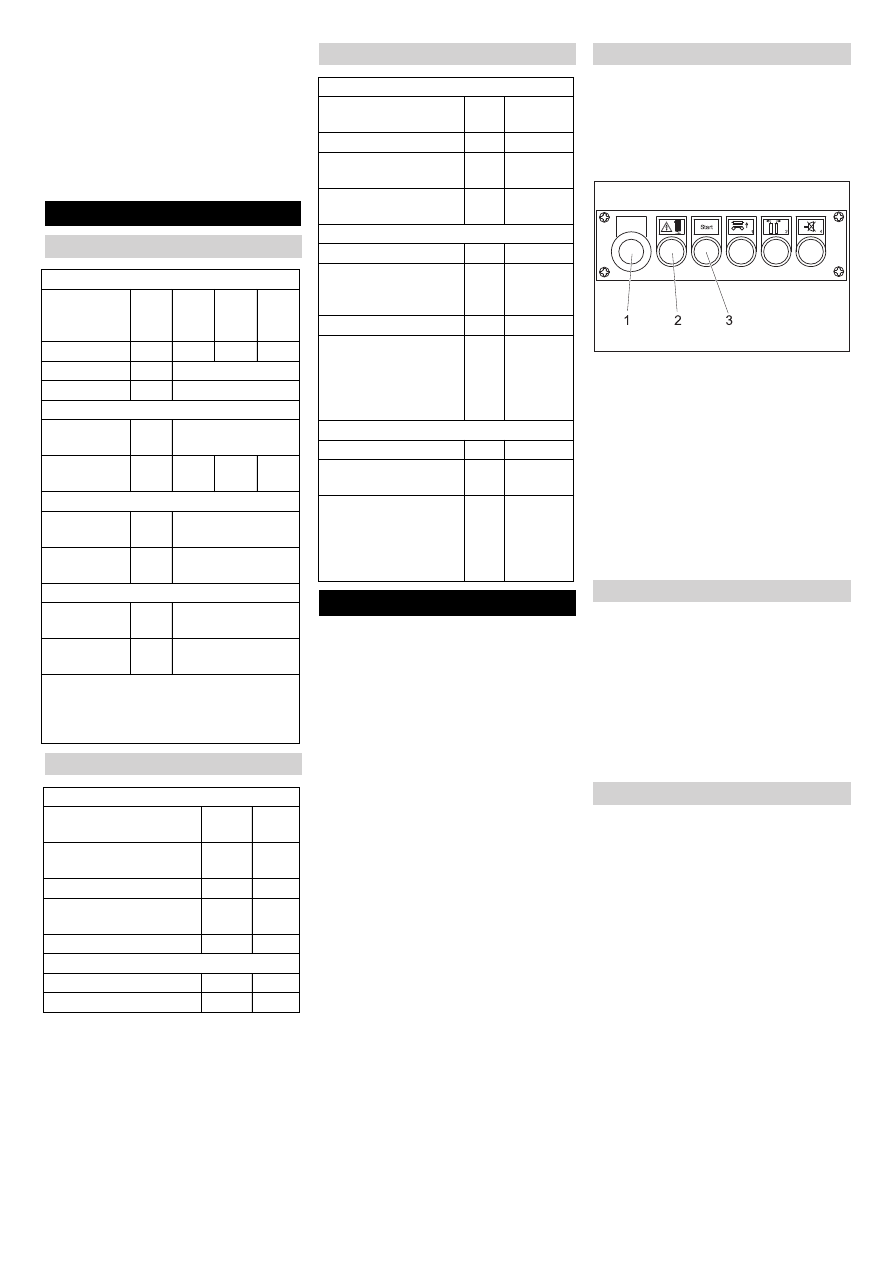

1 Emergency-stop button

2 Control supply voltage/normal position

button

3 Start key

Pull all emergency-stop buttons to un-

lock them.

Set automatic/manual switch at the

feeder to automatic.

Press control supply voltage/normal po-

sition button on the operating point for

manual mode.

The plant is again ready for operation and the

the vehicle being washed can be driven in.

Stop valve opens for water and com-

pressed air.

Set main switch on the feeder to “1”.

Set automatic/manual switch to auto-

matic.

Press control supply voltage/normal po-

sition button on the operating point for

manual mode.

The plant is again ready for operation and the

the vehicle being washed can be driven in.

몇

Warning

In order to avoid damage to the vehicle, the

following precautionary measures have to

taken on the vehicle before starting the

wash plant:

Close windows, doors and roof space.

.

Push in antennas, fold over in direction

of rear or dismantle

.

Fold in large or wide overhanging mirrors.

Check vehicle for loose vehicle parts

and dismantle them, e.g.:

–

chrome strips

,

–

spoilers

,

–

bumpers

,

–

door handles

,

–

exhaust pipes

,

–

wind-breakers

,

–

tilt ropes

,

–

sealers

,

–

anti –dazzle visors attached on the ve-

hicle

,

–

racks.

Bleed dosing pump

Specifications

Dimensions

Plant dimensions

CB 1/

23

Eco

CB 1/

25

Eco

CB 1/

28

Eco

Height

mm

3150 3350 3650

Width

mm

3500

Depth *)

mm

2020

Vehicle size limits dimensions **)

Washing

width

mm

2300

Washing

height

mm

2300 2500 2800

Washable vehicle lengths ***)

without safe-

ty distance

mm

5800

with safety

distance

mm

5270

Hall width

with safety

distance

mm

4500

without safe-

ty distance

mm

4050

*) rotating roof brush, rotating side-brushes

**)almost all the vehicles can be washed

within these dimensions

***) For driving track length of 9000 mm

Features

Wash brushes

Diameter of side-brushes

Side

mm

965

Side-brush rotation

speed

1/min

107

Diameter of brush Roof

mm

880

Brush rotation speed

Roof

1/min

127

Portal drive speed

m/min

0...20

Sound level

Brush cleaning

dB(A)

67

Drier operation

dB(A)

87

Connection values

Electrical connection

Voltage

V

400/3~, P,

N

Frequency

Hz

50

Connection output Ba-

sic plant

kW

approx. 10

Pre-securing Control

cabinet

A

max. 35

Water connection

Nominal width

Inch

1

Flow pressure accord-

ing to DIN 1988 (with

100 l/min)

MPa

(bar)

0,4...0,6

(4...6)

Temperature

°C

max. 50

Water consumption/ve-

hicle with 0.45 MPa

(programme-depend-

ent with 4.5 m vehicle

length)

l

80...210

Compressed air connection

Nominal width

Inch

1/2

Pressure

MPa

(bar)

0,6...0,8

(6...8)

Consumption/Washes

(without anti-frost de-

vice, programme-de-

pendent with 4.5 m

vehicle length)

l

200

Operation

Switching on after emergency-stop

Start up

Preparing the vehicle

24

EN